Dependable Oxygen and Ozone Solutions

We design and build systems to last, with quality in mind.

Proudly located in America’s heartland,

we offer high-quality products and unmatched customer service. We design and manufacture oxygen and ozone systems for commercial and industrial applications.

Oxygen and ozone are natural gases and can reduce or otherwise eliminate the need for chemical applications. This green technology is not only good for our planet, but also more efficient than harmful chemicals.

Our Story

How We Started

Founded in 2010, Heartland Oxygen Systems LLC is a Kansas City-based small business that was formed as a spin-off of Adaptive Ozone Solutions Inc., with an initial focus on building oxygen generators for veterinary clinics. We saw an opportunity to build a better oxygen system, one that is built for performance and longevity and leverages green technology. Our systems were built with safety features and redundancies to allow for easy maintenance without a complete system shutdown.

Where We Are Now

Heartland’s early years were spent in a small corner of a customer’s workshop located in Merriam, Kansas. Over the years we have grown and relocated from Merriam to Shawnee to Overland Park, Kansas. Today we operate in a 10,000 sq. ft. facility in Overland Park and will soon expand to 14,000 sq. ft. Being centrally located, we are well-suited to service the U.S. and North America.

What’s in a Name

We are called Heartland Oxygen Systems because we take pride in our home and our culture. We believe in kindness and treating people with equity. It is important to do business locally and support small businesses whenever possible. With today’s technological advancements, more and more commerce is conducted electronically, but we strive to still make personal connections and to do business with a handshake.

What We Can Do For You

We pride ourselves on being problem solvers and enjoy the challenge of designing the best system to meet our clients’ needs. Since our generators are built to order, we are able to provide design flexibility that you aren’t able to get with an off-the-shelf system, as well as customization options if needed. We don’t take shortcuts and hold ourselves to high standards for quality and safety. Our standard systems are UL-certified, so you can rest assured that safety regulations are followed.

As a company, we have more than 30 years of experience in oxygen and ozone with a primary focus on veterinary, wastewater and aquaculture applications. We are thankful for the great success we’ve had in these markets and are actively researching and vetting opportunities for additional applications.

We would love to chat with you to learn about your needs and discuss how our systems can be a reliable solution for your business.

A preview of our primary applications.

Although these markets have been our primary applications, there is vast potential for other implementations of our oxygen & ozone systems.

Wastewater

Oxygen systems can be used in wastewater applications to support the growth of aerobic bacteria, which break down organic matter in wastewater. These systems increase the dissolved oxygen levels in the wastewater, facilitating the bacterial degradation process and ultimately leading to cleaner, safer water for communities and their inhabitants.

Aquaculture

Oxygen systems are used in aquaculture to provide sufficient oxygen levels for fish and other aquatic organisms to survive and thrive. These systems typically involve the use of diffusers or aerators to introduce oxygen into the water, and can be adjusted to maintain optimal oxygen concentrations for specific species and environmental conditions.

Veterinary

Oxygen systems play a critical role in veterinary hospitals by providing a reliable, cost-effective and constant source of oxygen to assist with animal respiration during surgeries, emergency procedures, and other treatments, as well as supply for ICU cages. These systems are essential for ensuring the safety and well-being of animals in need of medical care.

Wastewater

Our systems are designed to be installed in lift stations as treatment solutions for force mains. Our high-pressure oxygen and ozone systems control and eliminate hydrogen sulfide (H2S) by creating an environment with elevated dissolved oxygen (DO) and dissolved ozone to minimize anaerobic bacteria activity. The application is energy efficient and occupies a small footprint in the lift station. At the injection point on the force main, we have options to utilize either nanobubbles or microbubbles to increase the dissolved oxygen and ozone.

Published university studies have verified that our treatment application of injecting oxygen and ozone in the force main using nanobubbles or microbubbles significantly reduced or eliminated H2S at the end of the force main. In one study with a force main that is approximately one mile in length, our system completely eliminated the H2S and showed O2 readings of 22.0%.

Heartland Oxygen Systems also designs oxygen systems to be installed as treatment solutions for dissolved oxygen in effluent. These systems are installed at the wastewater plant and can be sized to meet the needs of the facility’s output requirements.

Our systems can be adapted to fit any length of force main with varying retention periods, making our system a great option for all lift stations.

Benefits of Using Oxygen Systems for Wastewater Applications

Cost Savings

Eliminating Hydrogen Sulfide (H2S) with oxygen and ozone reduces the need for chemical treatment, saving your organization money, labor and time by not having to purchase, store or transport chemicals.

Fewer Byproducts to Remove

With an increase in dissolved oxygen and thus less need for chemical treatment, there are less chemical byproducts that must be removed from the wastewater at the treatment plant.

Less Frequent Maintenance of the Plumbing Network

The rate of corrosion occurring on mains and manholes is slower due to the elimination of hydrogen sulfide.

Higher Quality of Plant Output

The water being returned back to nature from the plant is of higher quality due to the increased dissolved oxygen content of the water.

Greater Plant Capacity

Increasing the dissolved oxygen in sewer mains reduces the load on the plant.

Aquaculture + Aquaponics

Our systems are designed for fisheries, aquaculture and aquaponic operations. Our high-pressure oxygen systems increase dissolved oxygen (DO) in water to maximize plant and animal growth. The application is energy efficient and occupies a small footprint. We have options at the injection point to utilize either nanobubbles or microbubbles to increase the dissolved oxygen.

Heartland Oxygen Systems designs products to control dissolved oxygen in water that allows customers to customize oxygen levels that best fit your operations. Our systems can be adapted to fit any size of aquaculture application, making our system a great option for fishery or aquaculture operation.

Benefits of Using Oxygen Systems for Aquaculture and Aquaponic Operations

Cost Savings

Our high–pressure oxygen systems are a cost-effective alternative to bottled or liquid oxygen.

Reduced Nitrogen Levels

Our systems inject much less nitrogen into the water compared to ambient air pumps.

Healthier Fish and Plants

Increasing the dissolved oxygen content in the water supports healthier fish and plants.

Increased Facility Operations

Healthier fish and plants lead to faster growth rates, increasing your facility’s production capacity.

Generator Details

All of our systems generate 90-95% pure oxygen.

- Generators require USA standard single-phase 120 VAC power supply.*

- Individual generator requirements

- HOX-060-3 generator: 120 VAC 30 amp circuit, 1-1/2 HP (1.2 kWh)

- HOX-040-3 generator: 120 VAC 25 amp circuit, 1-2/3 HP (1.7 kWh)

- HOX-008-2 generator: 120 VAC 20 amp circuit, 2/3 HP (0.7 kWh)

- Optional oxygen storage tanks (80 or 120 gallons) are available to reduce generator runtime and can be combined for greater volume capacity.

- Maximum pressure for individual generators

- HOX-060-3 generator: 165 psi

- HOX-040-3 generator: 155 psi

- Smaller generators: 90 psi

*The kWh on average in the US is 23 cents and varies by location.

Generator Capacity

Cubic Feet (SCFH)

Footprint

Weight

Generator HOX-060-3

Liters (LPM)

30

63.5

Pounds (Lb per Hour)

5.25

48" x 48" x 12"

500 lbs

Generator HOX-040-3

Liters (LPM)

20

Cubic Feet (SCFH)

42.3

Pounds (Lb per Hour)

3.50

Footprint

42" x 36" x 12"

Weight

250 lbs

Pounds (Lb per Hour)

0.69

Footprint

Weight

125 lbs

Generator HOX-008-2

Liters (LPM)

4

Cubic Feet (SCFH)

8.4

24" x 24" x 12"

System Flexibility

30

30

90

30

Oxygen liter flow rates produced by a single cabinet range from 4 LPM up to 30 LPM. Generators can be easily combined to achieve greater total outputs.

- Multiple generators can be combined to produce up to 360 LPM (762.7 SCFH) total.

- A single control cabinet can synchronize the operation of up to six generators.

- Up to two control cabinets can be combined to synchronize up to twelve generators.

System Benefits

easy to monitor

Each generator includes instrumentation to facilitate straightforward system monitoring, as well as remote alarm capabilities.

customizable, plug-and-Play

Our systems are built to order allowing design flexibility and customization, including the ability to define a specific dissolved oxygen level. Our plug-and-play technology easily accommodates any future increases in oxygen needs.

Small footprint

Our units are stackable and require only 10 square feet of floor space, reducing the overall footprint of the system.

Born and raised in the Kansas City metro, Derek attended Rockhurst High School and Kansas State University. He graduated with a Bachelor of Science in Agricultural Economics with a minor in Accounting. Following his time at K-State, Derek went to work for Adaptive Ozone Solutions Inc. (AO3) as a technician from 2007-2010. During his years with AO3, he learned the intricacies of oxygen and ozone systems, primarily as treatment options for wastewater and veterinary hospitals. He became an expert on oxygen and ozone systems from beginning to end including building, testing, installing, supporting and troubleshooting post-installation, performing maintenance, and collaborating on product development.

After Adaptive Ozone Solutions closed in 2010, Dale and Derek were approached by previous customers about continuing to build oxygen systems for veterinary clinics because the systems were some of the most reliable in the marketplace. A few months later, Heartland Oxygen Systems was formed to meet this need and operated out of a small facility in Merriam, Kansas.

During Heartland’s early years, Derek also worked full-time for ProAg, a crop insurance provider, from 2010-2023. During his 13 years with ProAg, he held multiple progressive leadership positions including Claims Processing Manager, National Claims Manager, and National Sales Manager. With Heartland Oxygen System’s continued growth in existing markets and prime potential to expand into additional markets, Derek decided in early 2023 that it was time to leave his enjoyable and successful career in crop insurance to pursue his dream of working for his own business full time.

Outside of work, you’ll likely find Derek either spending quality time with his wife Grace, traveling, or out on the golf course.

Derek Eltiste

President & Owner

Dale Eltiste

Chief Operations Officer

Dale is from a small town in north-central Kansas and moved to Kansas City to start his professional career after graduating from Kansas State University with a Bachelor of Science in Finance. He has over 20 years of experience designing, manufacturing, and selling oxygen and ozone systems. Prior to Heartland Oxygen Systems, Dale was President/Founder of Adaptive Ozone Solutions (AO3). AO3 was reorganized in 2010 with the formation of Heartland Oxygen Systems.

Dale has held various executive positions, many with entrepreneurial companies, prior to founding AO3. Those positions include:

- BeyondNow Technologies, Inc. – Chief Financial Officer

- Brush Creek Enterprise Center – Executive Director

- Innovative Material Systems, Inc. – Vice President Finance and Administration

- Cypress Systems, Inc. – President

- FluidSolutions, Inc. – President & Treasurer

- Marion Merrell Dow, Inc. – Vice President Administration

- Arthur Andersen – Certified Public Accountant

Dale enjoys finding new market opportunities and designing oxygen and ozone systems. Being able to work with his son, Derek (President and Owner of Heartland Oxygen Systems), brings him joy and pride. When not working he enjoys spending time with his significant other and playing golf.

Kaid Hommon

Production Manager

Kaid is originally from Smith Center, KS and has lived in the Kansas City area for 20 years. He joined Heartland Oxygen Systems in 2019 after 8 years in the hemodialysis industry where he was the Production Manager for Medical Solutions International in Merriam, KS. Kaid was involved in the manufacturing and installation process for a variety of products. Kaid’s background and experience in the dialysis industry strengthened his skills to make the transition to Heartland Oxygen Systems as seamless as possible.

As the Production Manager at Heartland Oxygen Systems, Kaid helps to organize shipping schedules, track down components, and work with our vendors and customers to help facilitate any needs.

During his free time, Kaid enjoys following most of the Kansas City sports teams and playing golf.

Why Choose Us?

First-Class Customer Service

- Customer service is a cornerstone to our business; we respond to calls and emails within 1 business day or sooner.

- We are invested in our customers’ success and satisfaction.

Scalable Products

- Our oxygen systems are designed to scale from 4 LPM to 360 LPM and can be easily integrated to fit your specific needs.

- We have designed our oxygen and ozone systems to produce up to 165 PSI, which allows for greater solubility in water or wastewater.

Proven Applications

- Our wastewater application has been verified with published studies from 2 separate universities proving the elimination of hydrogen sulfide in wastewater using oxygen and ozone.

- Our oxygen generators are a safer alternative to bottled or liquid oxygen.

Cost-Effective Solutions

- The return on investment for our systems is often short, enabling your company to utilize financial resources more prudently.

- Our generators have been designed with longevity in mind. With proper maintenance, our systems are built to last.

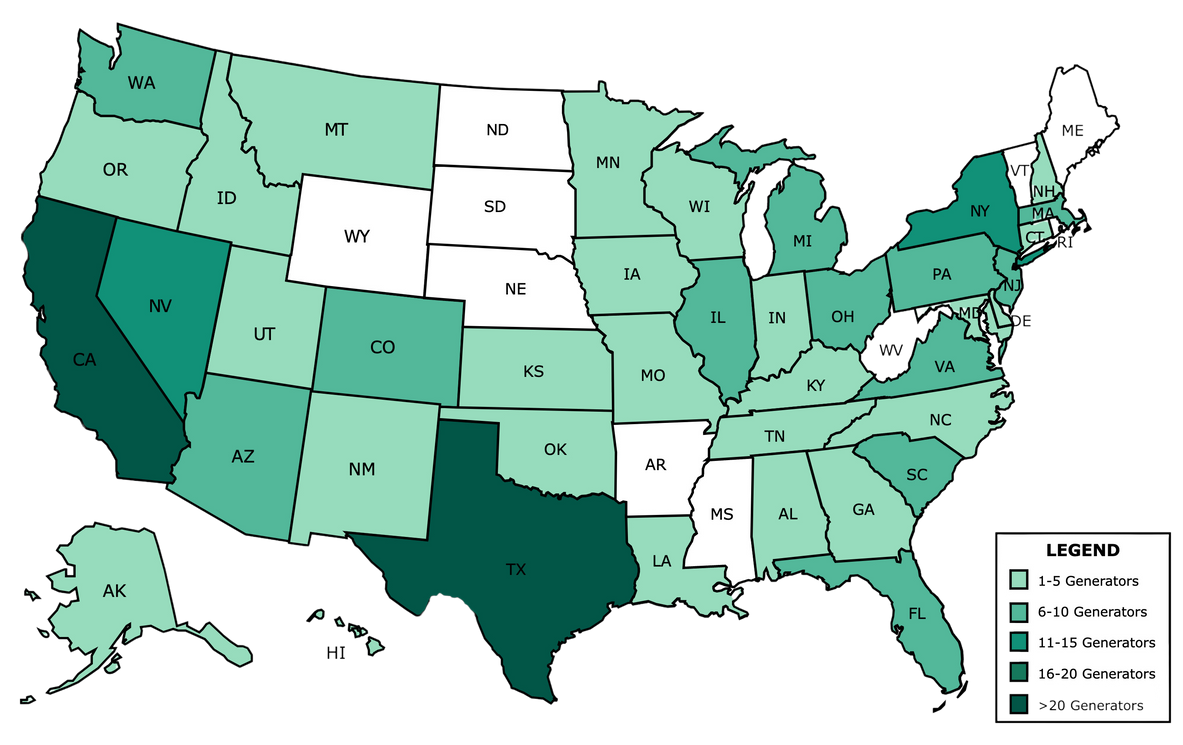

Our Footprint

40

States served

445

Generators sold

3

Canadian provinces

served

14

Years in business

What Our Clients Say

“We were adding a chemical called bioxide to a lift station that has approximately 400,000 gallons a day of sewage to eliminate hydrogen sulfide at the end of the force main. Dale and his company came in and installed an ozone machine and it has been working perfectly with routine maintenance and eliminated the use of this chemical at approximately 4 dollars per gallon. Trips to this lift station to add this chemical daily was now eliminated.”

- Bob Z.

Green Bay Metropolitan Sewerage District

“[…] Since the pure oxygen system was installed the City of Manhattan has had zero odor complaints from this force main. The pure oxygen system is easy to operate, and maintenance is easy as well. The unit does not use any chemicals like many other odor control systems and because it is an oxygen system it can be mounted inside of a lift station with a minimal footprint as long as fresh air is provided to the unit and cooling provided.”

- Gerry D.

City of Manhattan, KS